How to Build a Small House Kit: Shipment and Preparing for Delivery

Here’s an overview of the delivery process, including the first steps in SIP home construction, followed by answers to common questions about shipping and delivery of your kit home.

Preparing for the Delivery of Your House Kit

Before the arrival of the truck with your small house kit, you should have already obtained your building permits, which gave you legal permission to prepare your lot and complete your kit home’s foundation, including the bottom plate.

Depending on the model and size of a house kit that is purchased from Mighty Small Homes, customers typically receive a shipment containing about 25-40 structural insulated panels (SIPs) for the walls and roof. Each SIP weighs about 120 pounds, but they are more awkward than heavy—two-to-four people can easily carry these panels.

When the truck pulls up to your building site, you and your crew are on the clock. Typically, you will have two hours to unload the panels, and the trucking company will invoice you for any time over that threshold.

Tip: When you unload your kit home’s panels, place them in an area on your lot that is opposite from where you’ll be placing your first walls. This makes maneuvering the panels during construction much easier.

Once the panels are all unloaded, you can immediately begin placing the wall panels on your foundation, assuming the preliminary work has been completed.

Getting Started with SIP Panels

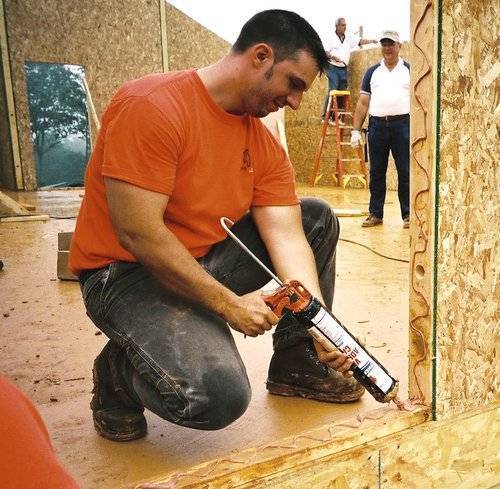

As soon as the panels are unloaded from your truck, you can begin assembling your new house kit with your building crew. Most kits from Mighty Small Homes can be under roof in 1-2 days.

You should have all the basic construction tools ready, including a power saw, power drill, level, and hammers. Our home kit packages include all the fasteners and special tools you need for working with our panels.

Look over all the panels and your plans (again) to identify and match the numbers marked on the wall panels. You’ll start with W1 and W2, which are corner panels. Once these walls are up and stable, your crew can begin following your plans to install the remaining numbered panels in sequence.

When it comes to installing the ridge beam (only required in certain models) and roof panels, we advise that you plan on budgeting for a hydraulic boom lift. While it may be possible for your crew to complete this stage of the building process by carefully using ladders, using a lift will be both faster and safer.

Shipping House Kits to Remote Building Sites

Rural or primitive locations may not be accessible for the semi-truck that delivers your house kit. If your home can only be reached via narrow, unpaved roads with sharp turns, it may be too unsafe for a truck driver to safely navigate. Similarly, a truck should be able to turn around if the road deadends.

Without access for the truck, you may need to move the panels yourself from a drop location using a pickup or flatbed truck. Be sure to factor in the need to protect your panels from inclement weather if a rainstorm rolls in during your delivery window.