Breaking Down the Costs of DIY House Kits Made with SIPs

Mighty Small Homes offers prefabricated house kits built with structural insulated panels (SIPs). These kits provide a tight, well-insulated shell that can be assembled quickly, resulting in homes that use 50–60% less energy for heating and cooling than traditional construction.

SIP construction also delivers impressive strength and longevity, with panels engineered to withstand high winds and heavy loads. In short, a SIP kit home gives you a strong, eco-friendly structure that can save money in construction and in long-term utilities.

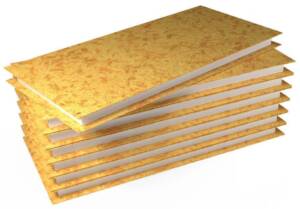

What Are SIPs (Structural Insulated Panels)?

SIPs are high-performance building panels made by sandwiching a rigid foam insulation core between two structural facings, typically oriented strand board (OSB). In simple terms, each panel acts as a pre-insulated wall or roof section. Together, they form the structural frame of your house and also insulate it. Panels are pre-cut in a factory with window and door openings, then delivered to your site ready for assembly.

The result is a solid, airtight shell that goes up faster than stick framing and offers superior energy efficiency. If you have basic carpentry skills or a good contractor, you can bolt the numbered panels together on a prepared foundation and get your home under roof in days instead of weeks.

Base Kit Costs and Cost per Square Foot

Before choosing a model, it helps to understand how the base kit cost is calculated.

One of the first factors to consider is the base kit price of the SIP home. This is the upfront cost for the kit itself—the weather-tight shell package. Calculating this cost accurately requires ordering engineer-certified blueprints (and ideally, MEP plans) for your kit before panel production can begin at the factory.

Mighty Small Homes’ base kit prices vary by model and size, generally ranging from the mid-$20,000s for a tiny cabin to around $70,000 for a larger 1,200-square-foot home. That equates to roughly $50–$100 per square foot, with smaller structures on the higher end of the range due to fixed costs such as engineering and shipping.

Calculate Cost of A Kit + Options

|

Model |

Size (sq. ft.) |

Estimated Cost |

Approx. Cost per Sq. Ft. |

| “Tiny” Kit | 192 | $25,000 | ≈$130 |

| Large Model | 1,200 | $65,000–$70,000 | ≈$55–$60 |

Why the Spread in Cost per Square Foot?

Large kits cost less per square foot because the material and manufacturing costs are spread across more areas. All kits include the core structural materials needed to build the exterior shell: pre-cut SIP wall and roof panels, house wrap, roofing underlayment, plate lumber, fasteners, caulk, interior framing lumber, wiring chases, and detailed assembly instructions. In other words, the base kit gives you a fully insulated, dried-in shell ready for exterior finishes.

Upgrades and customization will affect the kit cost per square foot. The standard kit comes with the essentials listed above, but you can add options such as thicker wall panels, additional window or door openings, exterior siding or roofing materials, loft or porch components, and more. These upgrades naturally add to the base kit price.

For instance, opting for the manufacturer’s window and door package or premium siding will raise your kit cost but may save time and ensure a perfect fit. When budgeting, start with the base kit cost for your chosen model and size, then factor in any add-ons you plan to include.

Material Cost Breakdown: From Shell to Finishes

Once you have the SIP shell kit, what other material costs will you incur to make the house move-in ready? It helps to break these down by component. We compare basic contractor-grade options versus higher-end premium choices to show how your selections can affect the budget.

Roofing

![]() The kit includes roof panels and felt underlayment, but you supply the final roofing finish. Contractor-grade asphalt shingles are affordable, around $3–$5 per sq. ft. installed. Upgrading to premium metal roofing or architectural shingles costs roughly twice as much but provides greater durability and longevity.

The kit includes roof panels and felt underlayment, but you supply the final roofing finish. Contractor-grade asphalt shingles are affordable, around $3–$5 per sq. ft. installed. Upgrading to premium metal roofing or architectural shingles costs roughly twice as much but provides greater durability and longevity.

For a small home roof (~1,000 sq. ft.), budget about $3,000–$5,000 for basic shingles versus $8,000+ for high-end metal roofing.

Exterior Siding

![]() SIP walls require exterior cladding. Basic vinyl siding or engineered wood panels are standard contractor-grade options, averaging $4–$8 per sq. ft. installed. Premium siding options, such as fiber cement or natural cedar, range from $10 to $14 per square foot. Including trim and soffits, a 600-sq.-ft. might cost $5,000–$8,000 on simple vinyl siding, while upscale materials could reach $10,000–$15,000.

SIP walls require exterior cladding. Basic vinyl siding or engineered wood panels are standard contractor-grade options, averaging $4–$8 per sq. ft. installed. Premium siding options, such as fiber cement or natural cedar, range from $10 to $14 per square foot. Including trim and soffits, a 600-sq.-ft. might cost $5,000–$8,000 on simple vinyl siding, while upscale materials could reach $10,000–$15,000.

Windows and Exterior Doors

![]() These can be purchased through Mighty Small Homes as upgrades or sourced separately. Standard double-pane vinyl windows cost roughly $200–$400 each installed, and a basic fiberglass exterior door $300–$500.

These can be purchased through Mighty Small Homes as upgrades or sourced separately. Standard double-pane vinyl windows cost roughly $200–$400 each installed, and a basic fiberglass exterior door $300–$500.

Premium windows with triple-pane glass and wood-clad frames run $800–$1,200+ each, and high-end doors $1,000+.

A small home with 6–8 windows and 1–2 exterior doors could spend ≈$3,000 on budget options versus $8,000+ for premium units.

HVAC System

![]() Small, well-insulated SIP homes often use ductless mini-split systems. A basic one- to two- zone mini-split costs $2,000 to $5,000, including equipment and installation.

Small, well-insulated SIP homes often use ductless mini-split systems. A basic one- to two- zone mini-split costs $2,000 to $5,000, including equipment and installation.

A premium multi-zone system or high-efficiency furnace/AC setup runs $8,000–$12,000 installed, but still tends to be smaller and more efficient than systems in conventional homes.

Plumbing and Electrical (Rough-In)

![]() Even for DIY builders, licensed professionals usually handle major plumbing and electrical work. Combined material and labor costs typically range $8,000-$15,000 for a small home.

Even for DIY builders, licensed professionals usually handle major plumbing and electrical work. Combined material and labor costs typically range $8,000-$15,000 for a small home.

This includes water supply lines, drain/waste/vent piping, wiring, outlets, and breaker panel installation.

Using simple, contractor-grade fixtures keeps you near the low end. Complex layouts or premium fixtures raise the cost.

(Note: These figures exclude connections to utility mains or septic systems.)

Drywall

![]() The SIP shell already provides exterior insulation, but interior finish work still requires drywall for fire protection and painting. Drywall installation costs $1.50–$2.50 per sq. ft., so 600-sq.-ft. home with ~2,000 sq. ft. of wall and ceiling area might total $3,000–$5,000 installed.

The SIP shell already provides exterior insulation, but interior finish work still requires drywall for fire protection and painting. Drywall installation costs $1.50–$2.50 per sq. ft., so 600-sq.-ft. home with ~2,000 sq. ft. of wall and ceiling area might total $3,000–$5,000 installed.

Painting adds another $1.50–$3.00 per sq. ft. for primer and two coats of paint.

Flooring

![]() Flooring costs vary widely by material. Budget-friendly options like laminate planks, basic vinyl, or carpet run $3–$6 per sq. ft. installed. In an 800-sq.-ft. home, that’s $2,400–$4,800 for all floors.

Flooring costs vary widely by material. Budget-friendly options like laminate planks, basic vinyl, or carpet run $3–$6 per sq. ft. installed. In an 800-sq.-ft. home, that’s $2,400–$4,800 for all floors.

Premium flooring, such as hardwood or ceramic tile costs $8–$15+ per sq. ft. and can double the budget.

Many DIY builders mix materials — economical flooring in main spaces, upgraded finishes in key areas.

Cabinetry

![]() Kitchens often drive the largest interior costs. Contractor-grade cabinets with laminate counters average around $10,000 for a modest kitchen (~10’x10’).

Kitchens often drive the largest interior costs. Contractor-grade cabinets with laminate counters average around $10,000 for a modest kitchen (~10’x10’).

Premium cabinets and countertops can exceed $20,000+. Figures include materials only — add labor if you’re hiring installation.

Appliances and Fixtures

![]() Outfitting the kitchen and bath adds another major cost category. Basic appliance packages start at $2,000–$4,000, and premium sets run $8,000+.

Outfitting the kitchen and bath adds another major cost category. Basic appliance packages start at $2,000–$4,000, and premium sets run $8,000+.

Lighting and plumbing fixtures add up quickly. Standard light fixtures average $75–$150 each, while decorative options or recessed lights cost more. Plumbing fixtures like faucets and toilets range $100–$300 for standard quality.

A budget bathroom might use a $100 faucet and $150 toilet, while a premium one could feature a $400 faucet and $500 one-piece toilet. You can easily mix budget and high-end finishes to balance cost and design.

Quick Cost Comparison – Basic vs. Premium Materials

To help with budgeting, it’s useful to see how standard and premium materials differ across the main components of a SIP kit home.

|

Component |

Contractor-Grade (Budget) |

Premium-Grade (High-End) |

| SIP Wall Panels | Standard 4.5" EPS core, OSB sheathing, good R-value and strength (Included in base kit). | Thicker insulation or factory-applied finishes – higher R-value, custom look (upgrade adds cost). |

| Roof Structure | Basic SIP roof panels with standard pitch and OSB facing (included in kit). | Enhanced panels or insulated ridge beam for custom design (upgrade adds cost). |

| Exterior Roofing | Asphalt shingles (15–30 yr lifespan) – ~$3–$5/sq. ft. installed. | Metal roofing or premium shingles – ~$8–$12/sq. ft. installed, |

| Exterior Siding | Vinyl or engineered wood ~$4–$8/sq. ft. installed. | Fiber-cement or cedar, about $10–$14/sq. ft. installed. |

| Windows and Doors | Vinyl double-pane windows (~$250 each), basic fiberglass door (~$300). | Wood-clad triple-pane windows (~$800+ each), designer doors ($1,000+). |

| HVAC System | Basic mini-split (~$2.5K DIY install). | Multi-zone or furnace + AC ($8K+ installed). |

| Kitchen Cabinets | Stock cabinets (~$5,000 for small kitchen). | Custom cabinets ($12K–$20K). |

| Countertops | Laminate or butcher-block ($20–$40/sq. ft.). | Granite or quartz($60–$100+/sq. ft.). |

| Bathroom Fixtures | Standard tub, chrome faucet, basic vanity ($1K–$2K). | Tiled shower, designer fixtures ($5K+). |

| Flooring | Laminate, vinyl, or carpet ($3–$6/sq. ft.). | Hardwood or tile ($10+/sq. ft.). |

| Interior Finish | Standard drywall, flat paint ($1.5–$3/sq. ft.) | Premium drywall, textured finish (higher cost). |

| Lighting and Electrical | Basic fixtures ($75 each), toggle switches. | Designer fixtures ($150+ each), dimmers, smart switches. |

| Plumbing | PEX piping, basic fixtures ($150 toilet, $100 faucet). | Copper, tankless water heater, designer fixtures ($300+ faucet). |

Note: Prices shown are illustrative installed costs. Actual prices vary by region and over time; always get current quotes.

As you can see, finishing the home can cost as little or as much as you allow. A bare-bones DIY approach with simple materials keeps the total build cost low, while high-end finishes can easily double certain categories.

For a typical DIY SIP kit home, interior finish materials often add about the same cost as the shell kit itself. For example, you might spend $50,000 on a kit and another $50,000 to finish it. The benefit is flexibility. You can decide where to save or splurge, using economical finishes now and upgrading later if needed.

Labor: DIY vs. Contractor Costs and Savings

Labor is the other major part of the equation when budgeting a SIP kit home.

Hiring a general contractor means paying for crew labor, subcontractors, and the builder’s overhead and profit.

By contrast, “DIY finished” estimates, like those provided by Mighty Small Homes, assume you act as the builder. You handle some work yourself and subcontract out what you can’t do. This approach can significantly reduce labor expenses.

To understand the breakdown, it helps to separate the assembly of the SIP shell from the interior finishing work.

Guide to Building Our Kit Home

Shell Assembly (Exterior)

This phase includes unloading the kit, erecting SIP wall panels, setting roof panels, sealing joints, and getting the structure weather-tight.

Some owners tackle this work with a few friends or local carpenters, while others hire a crew just for the shell. As a guide, having a builder assemble the shell can account for about 15% of the total project cost. Doing it yourself can save the same 15%.

Mighty Small Homes estimates that a small crew can assemble the basic structure of many kits in just a few days, thanks to the precise pre-cut panels and detailed instructions included.

Interior Finishes (Interior Build-Out)

Once the shell is up, plenty of work remains: framing interior partitions, running electrical and plumbing lines, installing drywall, flooring, cabinets, and trim. You might DIY some of these tasks and hire professionals for others.

Labor costs vary. Drywall finishing typically costs around $2 per square foot, while tile installers often charge by the square foot of tile. Additionally, carpenters may quote a few thousand dollars for trim and millwork.

Acting as your own general contractor means coordinating these trades directly and paying only for their labor and materials. This sweat equity can reduce overall costs by 15-30% compared to full turnkey builder pricing, depending on how much you take on.

DIY Savings Example

To put it in perspective, here’s how DIY labor savings might look for two different model sizes.

Example 1 – 600-sq-ft Cottage

A turnkey builder quote might be around $200,000 for a fully finished small home. The SIP kit could represent about $50,000 of that total.

By assembling the shell yourself (saving roughly 15% ≈ $30,000) and completing another $10,000 worth of interior tasks such as painting or fixture installation, you could bring the total down to about $160,000.

Mighty Small Homes’ website shows a DIY finished cost of about 2.5 times the kit price, versus a builder-finished cost of around 4–5 times, which aligns with roughly 30–40% savings for hands-on owners.

Example 2 – 1,200-sq-ft Home

A larger model might have a builder turnkey cost of $300,000, with a SIP kit cost near $70,000. If you handle shell assembly and some finishing tasks, you might save $40,000–$50,000 in labor, bringing the total project closer to $250,000 or less.

The more you DIY, the more you save, as long as you take on tasks you have the skills and time for.

Not all labor should be DIY. Complex or hazardous work like electrical wiring, HVAC setup, and gas plumbing must be done by licensed professionals. You can still save by handling prep and finishing work around those tasks.

DIY-Friendly Tasks vs. When to Hire a Pro

If you’re planning a DIY SIP home, these are common tasks homeowners take on to cut costs.

DIY vs Professional Tasks

| DIY-Friendly Tasks | When to Hire a Professional |

|---|---|

|

|

By planning to DIY where possible and contracting out where necessary, you’ll maximize savings and keep the project on schedule. It’s also smart to budget a contingency for labor. Even experienced DIYers sometimes bring in help if timelines slip or a task proves more complex than expected.

Working with Contractors: Who Supplies What?

When you hire contractors for parts of your SIP home build, material sourcing can affect cost and responsibility.

If You Supply the Materials

You control product selection and can choose the exact fixtures or finishes you want, often finding sale prices. This can save money since contractors sometimes add a markup to materials they buy.

However, discuss this upfront. Some contractors charge higher labor fees or won’t warranty the work if they don't supply the materials. Make sure any items you purchase meet the required specifications.

If the Contractor Supplies Materials

This option is simpler for you. Professionals ensure everything arrives on site when needed, and reputable builders may have access to trade discounts. The contractor also assumes responsibility for those materials---if something is wrong or delayed, they must resolve it. This route can reduce your risk but might raise costs. Always ask for receipts or a detailed materials list when you’re billed for materials.

Common Issues to Watch For

Common issues include timing and compatibility. For example, if you’re supplying a special-order front door or custom shower kit, delays in delivery could hold up the schedule. Coordinate closely with your contractor to avoid downtime.

Hybrid Approach

Let contractors provide bulk materials they use daily, while you supply finished items that affect style and budget. Homeowners often choose and buy lighting, appliances, flooring, and paint, whereas the contractor handles essentials like fasteners, pipe, and wire.

Clear communication is key. Include in your contract which materials are owner-provided and which are contractor-provided to avoid confusion later.

Plan Your Budget and Build Safely

Building a DIY SIP kit home is a rewarding way to save money and be hands-on with your new house, but it requires careful planning and realistic budgeting. By breaking down each component, you can develop a clear picture of what it will take to make your home move-in ready.

Remember to include hidden expenses, because they add up quickly. Set aside a contingency fund for unexpected costs or price changes.

Use the cost ranges and examples in this guide to tailor your project to your budget. If you need to cut costs, take on more work yourself, or start with standard finishes, you can upgrade later. If durability and efficiency matter most, invest in shell insulation, windows, or other hard-to-change elements before spending on cosmetic extras.

Above all, prioritize safety and quality. Hire professionals where required, follow building codes, and have your work inspected when needed. A well-built SIP home will reward you with decades of low maintenance, comfort, and energy savings.

FAQs

The base kit provides all materials for the dried-in shell—pre-cut insulated wall and roof panels, house wrap, underlayment, fasteners, caulk, blueprints, and interior framing lumber. What’s not included are the foundation, siding, shingles, windows, doors, and interior finishes.

Total cost per square foot varies widely based on finish choices and labor. As a benchmark, many DIY SIP homes range from $140–$200 per sq. ft., with higher costs when using a full-service contractor.

Yes. Mighty Small Homes’ estimates show DIY builders often save 25–40% compared to turnkey builds.

Many kit homeowners assemble the shell, paint, install flooring, or handle cabinetry to save money. Always hire licensed professionals for electrical wiring, plumbing connections, and HVAC installation.

Don’t overlook soft costs and site work. Budget for permits, inspections, and site preparation. Foundation work alone can be significant. Also plan for utility hookups and any fees from local authorities.