6 Reasons for Building Small Homes with SIPS

One of the biggest mistakes when building a primary or vacation home is overlooking Structural Insulated Panels (SIPs). With so many material and construction choices for building new homes, SIPs stand out for their proven performance. Choosing an alternative might end up costing more than you expect.

SIPs aren’t a recent or emerging trend. They’ve been in use since the 1930s, and modern-day SIPs deliver a smarter, faster, and more energy-efficient way to build.

This article explores the advantages of SIPs, and what to consider when planning a new SIP home construction. Plus, you’ll see examples of experts building SIP kits across the United States.

What Are SIPs?

SIPs are high-performance building panels for walls, floors, and roofs. Each panel comprises a rigid insulating foam core sandwiched between two structural facings, usually oriented strand board (OSB). Compared to traditional framing, SIPs offer stronger, tighter, and more energy-efficient construction.

A Brief History of SIPs

SIPs have been around longer than many people realize. First developed in the 1930s and gaining popularity during the energy-conscious 1970s, they’ve evolved into a proven, high-performance building material.

Today’s SIPs come in three main types: EPS (expanded polystyrene)—the most common and cost-effective; Polyurethane for higher insulation values; and XPS (extruded polystyrene), ideal for moisture resistance.

Over the decades, SIPs have proven their versatility. While widely used in residential construction of single-family homes, ADUs, and vacation cabins, commercial projects like offices, retail spaces, and schools have begun using them for the same advantages.

Why Should You Build with SIPs?

Choosing the proper building method has a lasting impact on your home’s comfort, costs, and performance. SIPs offer a compelling alternative to traditional stick framing by combining insulation, structural integrity, and speed in one system.

Whether you're building your first home, downsizing, adding a detached residence on your property, or investing in a rental property, SIPs deliver advantages that make them a wise, future-ready choice.

1. Energy Efficiency

SIPs dramatically reduce air leakage and thermal bridging, two of the traditional-built homes' biggest causes of energy loss. With continuous insulation built into every panel, SIPs maintain consistent indoor temperatures and ease the load on HVAC systems.

Homeowners report energy savings of up to 60% compared to stick-framed structures. SIPs lock in long-term utility savings and create a more comfortable living environment from day one. The airtight design also blocks out external noise and air pollution, creating a quieter and healthier indoor space.

2. Strength and Durability

SIPs create solid, monolithic wall and roof systems that outperform traditional framing in strength tests. These panels resist bending, shifting, and racking during high winds, earthquakes, or extreme weather.

Many SIP homes exceed building codes in hurricane and tornado zones, withstanding up to 150 mph winds.

The solid panels also offer protection from flying debris.

3. Faster Construction

With factory-cut panels arriving ready to assemble, SIP construction moves much faster than conventional home-building methods.

You don’t have to cut and measure lumber on-site, and walls go up in a fraction of the time. A typical one-story SIP kit home can be assembled by a crew of 4–6 people, with wall panels weighing about 100 lbs each.

Speeding up your build reduces labor costs, avoids weather delays, and gets your home built sooner.

4. Lower Labor Costs

SIPs reduce the need for skilled framing labor. Because panels arrive pre-cut and labeled, general laborers or DIYers can handle most of the assembly, with minimal need for experienced carpenters.

This makes SIPs ideal in regions facing labor shortages or high labor costs.

Faster builds also reduce total man-hours, helping you stay on budget while maintaining high-quality construction.

5. Sustainable and Eco-Friendly

SIPs support green building practices by minimizing job-site waste and maximizing energy efficiency.

Many manufacturers use recyclable materials and sustainable production processes. Because SIP homes use less energy over their lifespan, they also reduce your carbon footprint.

When you build with SIPs, you contribute to a cleaner environment while gaining long-term savings and comfort.

6. Precision and Consistency Grounded in Accuracy

Structural insulated panels are manufactured in a controlled environment, ensuring each panel meets exacting standards for squareness, level alignment, and dimensional accuracy.

This precision results in tighter fits, straighter walls, and a consistent high-quality finish throughout the home.

Many of the common errors associated with traditional stick framing, such as warping, gaps, or misalignment, are effectively minimized.

Real-World SIP Builds: Proof in Every Panel

Across the country, homeowners choose SIPs for reasons beyond the blueprint.

Some need to build fast to meet tight timelines or save on construction-loan interest. Others are driven by long-term energy savings or a desire for a more sustainable lifestyle.

Whether they live in the mountains of Montana, the rolling hills of Kentucky, or the humid coastlines of Florida, these builders have one thing in common – they chose SIPs for more innovative construction.

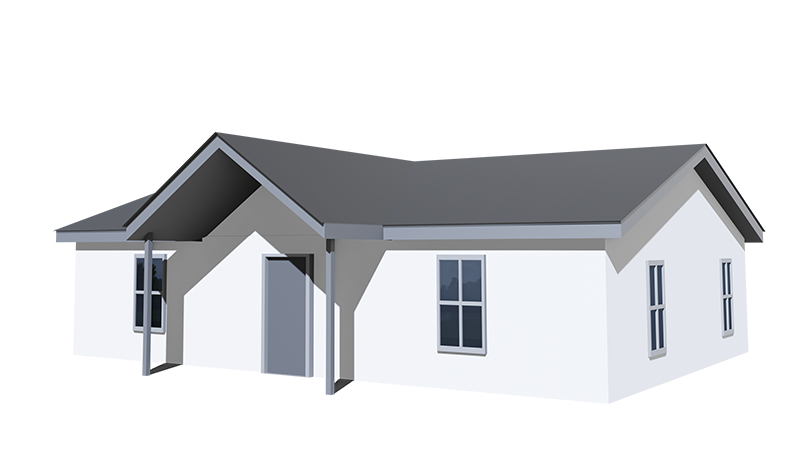

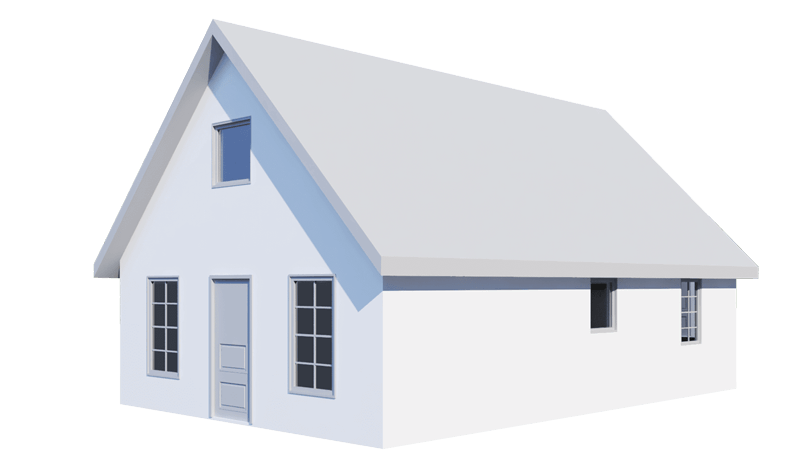

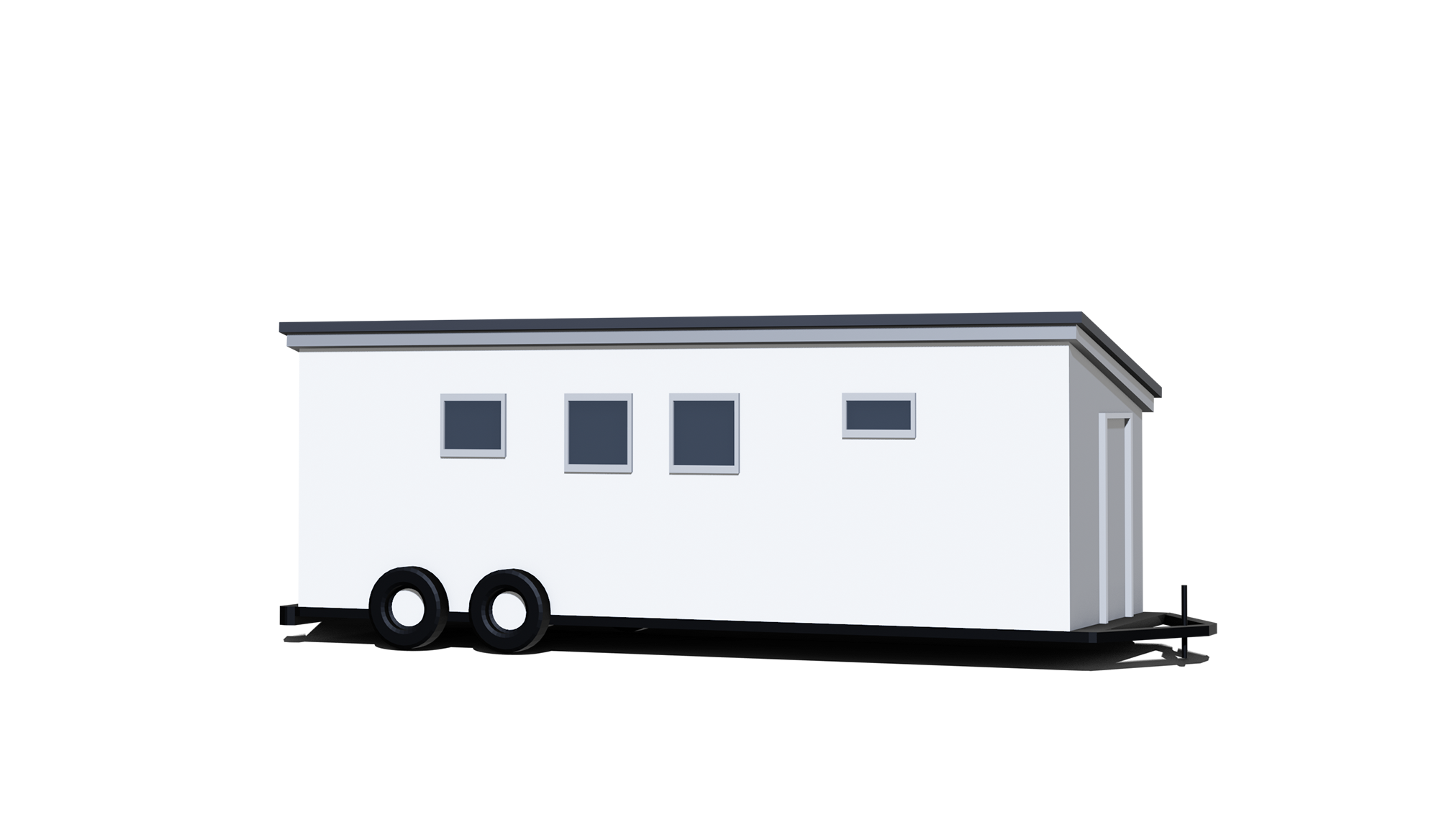

Mighty Small Homes offers numerous SIP home kit models and sizes to match lifestyles, climates, and goals. From compact, efficient cottages to sleek, contemporary designs, each model delivers consistent performance.

Click to See SIP Kits Come to Life

What to Consider When Planning

Building with structural insulated panels offers compelling advantages, but like any construction method, it comes with planning considerations that can affect cost, logistics, and overall success. Understanding these early in the process helps ensure smoother execution and better outcomes.

Upfront Material Costs

SIPs cost more than stick framing per square foot, but the added expense is offset by the savings they provide through faster builds, lower construction labor costs, and reduced energy bills.

Installation Equipment and Skills

Wall panels are light enough for hand assembly, but roof panels require a crane or boom lift. Basic carpentry experience is helpful, though less skill is needed than traditional framing.

Permitting and Financing

SIPs meet standard code requirements in most states. Be upfront with your lender and local building department. Permits documentation and engineering plans.

Precision, Not Revision

SIP builds require upfront design accuracy. Changes after production can be costly, so finalizing your design with MEP plans and precise dimensions before manufacturing the panels is critical.

Rethinking Residential Construction with SIPs

SIPs are reshaping how homes are built, whether for retirees seeking efficiency, families prioritizing indoor air quality, or developers focused on reducing construction time and long-term costs.

This building method combines speed, energy performance, and structural integrity in a streamlined prefab kit system. SIPs contribute to healthier living environments and better long-term value across various residential scenarios.

FAQs About SIP Home Construction

Yes. Structural insulated panels provide better insulation and airtightness than traditional home-building methods like stick frames.

The airtight construction of a prefab SIP home helps reduce mold, pollen, and outdoor pollutants.

Yes. Their monolithic design offers superior racking resistance. Testing shows panelized SIP homes can withstand 150 mph winds, and the panels provide added protection from flying debris.

Yes. Structural Insulated Panels (SIPs) significantly streamline the construction process because panels are pre-cut and delivered ready to assemble. Once they arrive at the build site, the walls and roof can often be erected and enclosed within one to two days. With fewer framing steps, integrated insulation, and reduced on-site labor, SIP construction moves quickly from foundation to lock-up, saving time without compromising safety or quality. From day one to move-in day, SIPs can reduce construction time by 30% to 60%.

Yes. They reduce construction waste and operational energy use.

The upfront cost of SIPs may be higher due to their materials. Significant savings in labor, construction time, and long-term energy use frequently offset these initial costs. Studies show a 55% reduction in labor costs and up to a 60% savings in utility costs.

The combination of sealed joints and solid insulation in a panelized SIP home creates a nearly continuous thermal envelope that prevents air from leaking out.

Yes. In fact, being pre-engineered and shipped to your site for quick assembly makes them perfect options for building prefabricated house kits.

SIPs are durable and can last as long as (or longer than) conventional framing, provided they are properly installed and protected from prolonged moisture exposure. Maintenance is similar to any other home: Keep the exterior envelope intact, and address leaks promptly.

Yes. SIPs are structurally strong and can support heavy cabinets, shelving, and wall-mounted TVs. It's best to plan where these items will be located on the panel in advance to account for any electrical wiring that may need to pass through it.

No, but it does require planning. Most SIPs have pre-cut chases for wiring and plumbing. Electricians and plumbers should be familiar with SIP construction, but most standard installations are straightforward. A mechanical, electrical, and plumbing plan (MEP) can save time and money.

SIP homes can be built on most standard foundations: slab, crawlspace, pillar and beam, or basement.

Yes. SIPs are used successfully in a wide range of climates, from Alaska to the Caribbean. Their high insulation value and airtightness make them ideal for hot and cold environments. See these homes built in the California desert, Michigan’s Upper Peninsula, and the Florida Coast.

No. Openings for doors and windows are pre-cut at the factory according to your plans. SIPs can accommodate large or custom openings, though very large spans may require additional engineering.

SIPs meet building code requirements for fire resistance. The OSB facings are treated for fire resistance, and gypsum board (drywall) is typically installed on the interior, adding further protection.