Rebuilding After Natural Disasters Using SIP Kits

Natural disasters like hurricanes, floods, wildfires, and tornadoes leave behind emotional and physical devastation. Homes and businesses are reduced to rubble, and families are displaced overnight. In the aftermath, there is an urgent need for emergency home replacement and rebuilding to restore a sense of normalcy.

However, survivors often face an uphill battle: shortages of building materials and skilled labor, rising construction costs, and the stress of prolonged displacement.

Traditional rebuilding efforts can be slow and frustrating. Shortages of workers and materials inevitably make reconstruction slower and more expensive after a disaster. Lumber, drywall, and insulation become scarce. Contractors are overbooked and difficult to secure, and prices for supplies surge due to high demand and strained supply chains.

Meanwhile, displaced families may be living in temporary shelters or crowded with relatives, anxious to rebuild their homes. The longer it takes, the greater the emotional toll, frustration, and uncertainty.

Understanding Rebuilding Dynamics After a Natural Disaster

Rebuilding after a disaster is complex, with logistical and emotional challenges that can derail even the most determined homeowners. To see how an innovative solution like Structural Insulated Panel (SIP) kits can help, it’s useful to understand the typical scenario survivors face in the aftermath.

- Material shortages: Following a major storm or wildfire, essential building materials often become scarce or experience delays. Supply chains are disrupted, and local stock is quickly depleted as everyone rebuilds at once.

- Labor shortages: The race for skilled labor is another serious obstacle. Local builders and contractors get overbooked for months, making it difficult to find available, qualified crews.

- Rising costs: High demand and limited resources cause price surges. Everything from plywood to plumbing fixtures becomes more expensive after a disaster. Labor rates often spike, too.

- Time pressure: Rebuilding is a race against time. Every extra day spent in a temporary shelter or FEMA trailer is difficult. With damaged infrastructure and seasonal weather changes approaching, there’s intense pressure to rebuild quickly.

- Emotional toll: The slow pace of traditional rebuilding can deepen trauma. Families experience frustration and anxiety as weeks turn into months without a permanent home. Dealing with contractors, insurance, and uncertainty adds mental and emotional strain. The longer the process drags on, the harder it becomes to regain a sense of stability and control.

What Families Need Most After a Disaster

In light of these challenges, people rebuilding after disasters tend to focus on a few key priorities. Beyond simply replacing what was lost, survivors are often motivated by the desire to rebuild smarter. They want homes that not only restore stability but also protect against future risks, reduce long-term expenses, and give families confidence that they won’t face the same vulnerabilities again.

- Build stronger and safer: After living through a catastrophe, homeowners want assurance that their new home will be disaster-resistant. Future-proofing the house against hurricanes, floods, or fires takes priority, with materials that offer superior strength and durability.

- Build faster: Speed is not a luxury, it’s a necessity. Solutions that enable quick rebuilding after hurricane damage or other disasters are highly appealing. Shaving weeks or months off construction means families can return home sooner, easing stress.

- Keep costs in check: With limited funds and often insufficient insurance coverage, controlling costs is essential. Homeowners need affordable rebuilding methods that minimize waste and avoid the inflated labor costs common in post-disaster construction. Predictable pricing provides peace of mind.

- Sustainability and resilience: Communities often adopt a "build back better" approach, looking for sustainable methods that also strengthen resilience.

With all these goals in mind, one question stands out. Could there be a faster, smarter, and stronger way to rebuild after a natural disaster? SIP kits may offer that path, addressing many of the pain points disaster survivors face and providing a route to recovery built on speed, strength, and savings.

Why SIP Kits Are a Smarter, Faster Way to Rebuild

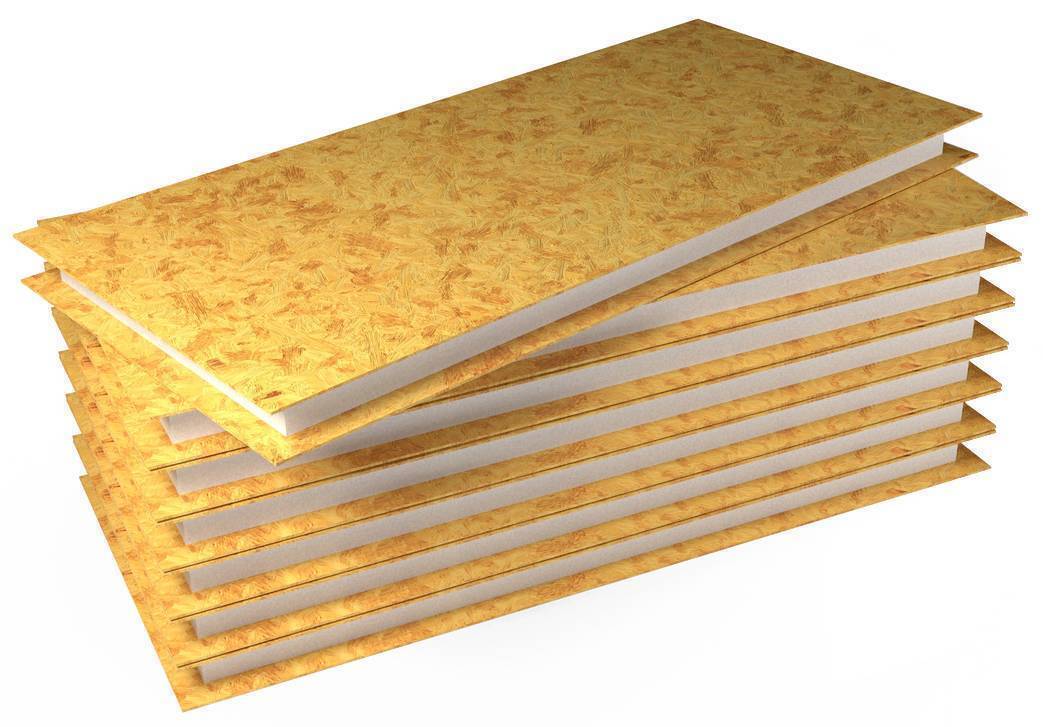

Imagine being able to replace a destroyed home quickly, without the delays and uncertainty of traditional construction. Structural Insulated Panel kits, or SIP kits, make that possible. These prefabricated home kits are made up of high-performance panels for walls, floors, and roofs. Each panel includes a rigid insulating foam core sandwiched between two structural boards. In simpler terms, a SIP panel is both your framing and insulation in one solid piece.

These panels are pre-engineered and cut to size in a factory, then shipped as a kit to the building site.

Because SIP kits are manufactured off-site with precision, they arrive ready to assemble. All wall sections, roof pieces, and floor panels are pre-cut and labeled according to the house plans. Builders or homeowners don’t need to spend time measuring and cutting lumber—the panels fit together like a puzzle.

This panelized, modular approach significantly streamlines the construction process, making SIPs an ideal solution for post-disaster housing. Instead of many months, the walls and roof of a SIP home can often be erected within one to two days once the foundation is ready. It’s a fast-track rebuilding method tailored for urgency.

Characteristics of SIP Kits as a Rebuilding Solution

- Ease of assembly: The kit includes all the necessary structural components to form the house's shell. With a small crew and basic tools, the panels are joined together following a straightforward plan. While not everyone can handle every step, SIP kits simplify the build enough that general laborers or volunteers can complete much of the work.

- Prefabricated accuracy: Since SIPs are produced in a controlled factory setting, there’s a high degree of precision and quality control. Every panel comes out square, plumb, and true to the design specs, eliminating many common on-site construction errors. The result is a house that fits together tightly with very little waste.

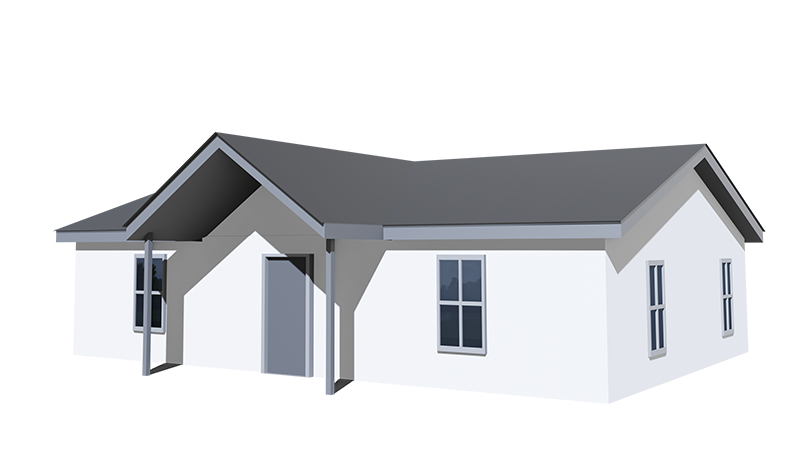

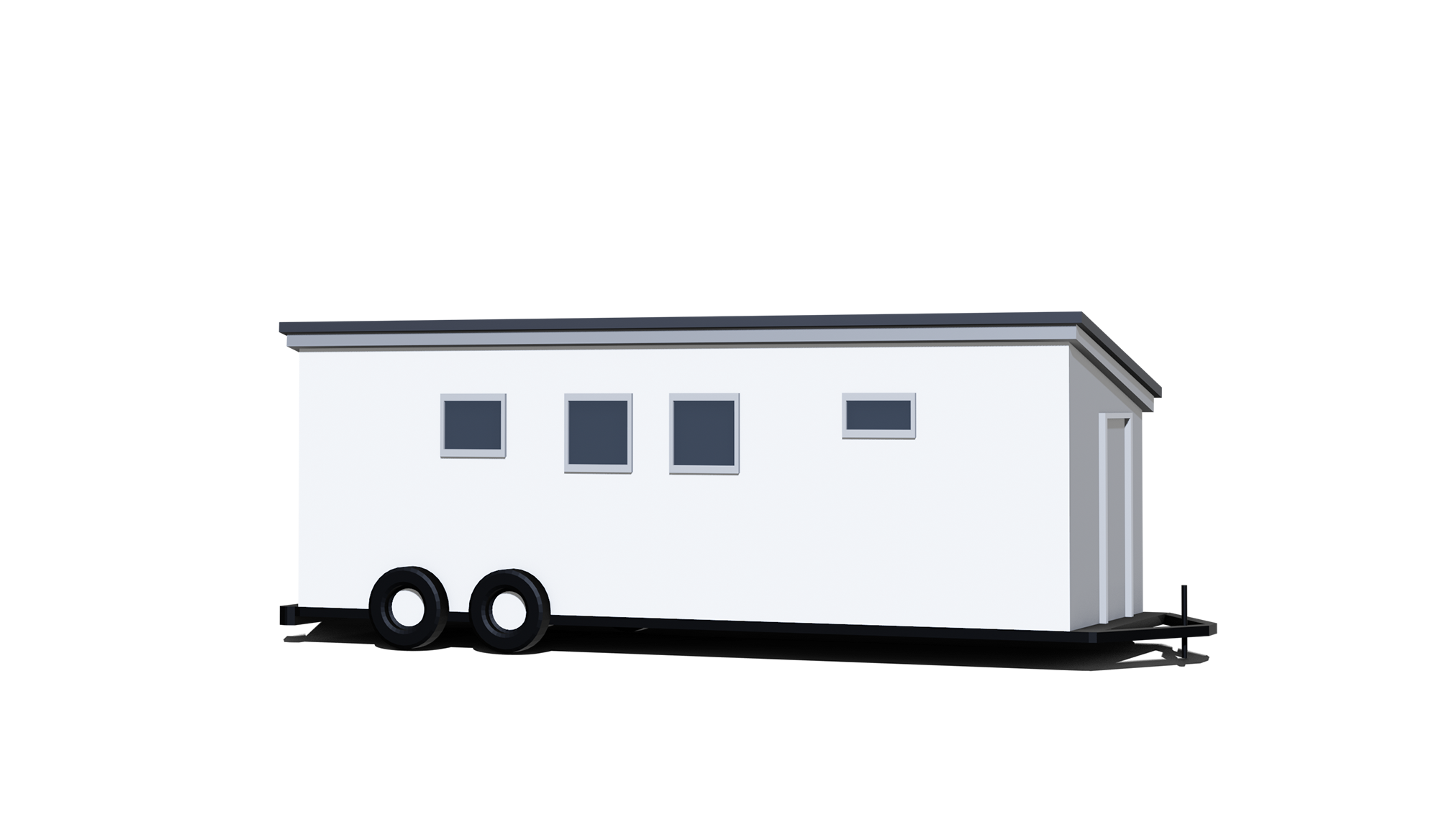

- Versatile design: Prefab SIP home kits come in various sizes and styles. Whether rebuilding a small cottage, a family home, or a duplex, SIP kits can adapt. They work for single-family homes, multi-family residences, and even light commercial structures. For example, Mighty Small Homes offers models ranging from tiny homes to multi-unit designs, and each can be customized in dimensions and floor plan to meet the owner’s needs.

- Minimal on-site infrastructure: In disaster zones, infrastructure is often damaged. One advantage of SIP kits is that they arrive with everything needed for the shell, reducing dependence on local supply stores.

SIP kits represent a smarter way to rebuild after a natural disaster. They combine structure and insulation in one, are pre-packaged for quick setup, and deliver reliable quality.

Why SIP Kits Stand Out After Disasters and Offer Emotional and Practical Relief

Choosing a SIP kit home for disaster recovery construction brings a host of advantages.

Beyond the technical advantages, SIP kits offer both emotional relief and practical benefits for people rebuilding their lives.

Rebuilding after hurricanes, floods, tornadoes, or wildfires requires more than just replacing what was lost. It demands speed, strength, affordability, and peace of mind. Structural Insulated Panel (SIP) kits deliver on all fronts, offering both technical advantages and human-centered benefits that make them a lifeline in disaster recovery.

Speed is Stability

SIP kit homes can be built significantly faster than conventional stick-built houses. Factory-cut panels arrive ready to assemble, fitting together like a puzzle. Walls and roofs can be erected in as little as 1–3 days once the foundation is prepared. This rapid assembly enables families to regain shelter quickly, restoring privacy, routine, and stability during an otherwise chaotic time.

SIP kit homes can be built significantly faster than conventional stick-built houses. Factory-cut panels arrive ready to assemble, fitting together like a puzzle. Walls and roofs can be erected in as little as 1–3 days once the foundation is prepared. This rapid assembly enables families to regain shelter quickly, restoring privacy, routine, and stability during an otherwise chaotic time.

Strength is Security

SIP structures are engineered for resilience. The solid, sandwich construction forms a monolithic shell that resists bending, shear forces, and impacts. Proven to withstand tornado and hurricane winds up to 150 mph, SIP homes exceed building code requirements in hurricane and tornado zones. For survivors, this strength translates into priceless peace of mind—confidence that their new home is built to endure future storms.

SIP structures are engineered for resilience. The solid, sandwich construction forms a monolithic shell that resists bending, shear forces, and impacts. Proven to withstand tornado and hurricane winds up to 150 mph, SIP homes exceed building code requirements in hurricane and tornado zones. For survivors, this strength translates into priceless peace of mind—confidence that their new home is built to endure future storms.

Efficiency is Affordability

SIP homes are 2–3 times more energy-efficient than traditional builds. Continuous insulation eliminates drafty gaps, significantly reducing heating and cooling needs. Homeowners often save 50–60% on utility bills, providing long-term financial relief at a time when budgets are tight. Efficiency isn’t just about comfort; it’s about affordability and sustainability.

SIP homes are 2–3 times more energy-efficient than traditional builds. Continuous insulation eliminates drafty gaps, significantly reducing heating and cooling needs. Homeowners often save 50–60% on utility bills, providing long-term financial relief at a time when budgets are tight. Efficiency isn’t just about comfort; it’s about affordability and sustainability.

Simplicity is Empowerment

![]() Because SIP kits arrive pre-cut, labeled, and ready to assemble, they require less specialized labor. General crews, volunteers, or even determined homeowners can handle much of the work, while contractors focus on electrical and plumbing. This simplicity reduces labor costs and empowers families and communities to take part in rebuilding. Neighbors, church groups, and volunteers can come together to build a SIP home, transforming recovery into a collective healing experience.

Because SIP kits arrive pre-cut, labeled, and ready to assemble, they require less specialized labor. General crews, volunteers, or even determined homeowners can handle much of the work, while contractors focus on electrical and plumbing. This simplicity reduces labor costs and empowers families and communities to take part in rebuilding. Neighbors, church groups, and volunteers can come together to build a SIP home, transforming recovery into a collective healing experience.

Predictable Costs

![]() Rebuilding is also an opportunity to build back better. SIP kits utilize sustainable materials and precise factory fabrication, resulting in minimized waste compared to traditional construction methods. Costs are more predictable, too. Pricing is determined mainly up front, avoiding the surprise overruns common in disaster zones. While panels may carry a slightly higher initial price than lumber, savings in labor, time, and energy bills quickly offset the difference.

Rebuilding is also an opportunity to build back better. SIP kits utilize sustainable materials and precise factory fabrication, resulting in minimized waste compared to traditional construction methods. Costs are more predictable, too. Pricing is determined mainly up front, avoiding the surprise overruns common in disaster zones. While panels may carry a slightly higher initial price than lumber, savings in labor, time, and energy bills quickly offset the difference.

SIP kits directly address the common pain points in post-disaster rebuilding. They build faster, perform better, waste less, and simplify the construction process. These benefits make SIP kits a compelling option for homeowners looking to rebuild smarter after a catastrophe.

Note: Not everyone can or should DIY an entire house, but SIP kits make it possible to contribute labor or manage the project with fewer trades. Many manufacturers provide detailed guides or even on-call support to assist homeowner-builders.

Overcoming Common Concerns About Rebuilding with SIPs

It’s natural for homeowners to have questions or hesitations about any newer building method. Here are some common concerns about SIP kits in disaster rebuilding, and why they don’t need to hold you back.

- “Do SIP kits cost more?”

While SIP panels can have a higher upfront price than raw lumber, it’s important to look at the total cost of rebuilding. In practice, faster assembly and lower labor needs mean you pay for fewer work hours, and the superior insulation saves money every month on utilities. These cumulative savings often offset the initial expense. Even if the material quote is higher, a SIP rebuild can end up being more cost-effective than a traditional one when you factor in reduced construction time and long-term energy efficiency.

- “Will my local builders or code officials accept SIPs?”

Modern SIP kits are an established building technology used across the country for decades—they’re not experimental. SIPs meet or exceed standard building code requirements in most areas, including hurricane and earthquake zones. Building departments are generally familiar with SIP construction, and manufacturers provide stamped engineering plans to ensure compliance. It’s always smart to communicate early with your local code officials, but there’s rarely a real barrier to using SIPs.

- “Are designs limited with SIP panels?”

Not at all. Design flexibility with SIP construction is very high. Kits can be customized for virtually any floor plan or style, from a simple cottage to a modern two-story home. Door and window openings are pre-cut per your architectural plans, allowing for custom layouts and large windows. SIPs can also be combined with other building systems if needed. Externally, a SIP home can look like any other—you finish it with standard siding, roofing, and interior drywall. Many people wouldn’t know a home is SIP-built unless told.

- “What about maintenance and longevity?”

SIP-built homes are durable and low-maintenance. The panels don’t have cavities where mold or pests can easily spread, unlike stud walls with batts. With proper installation and normal upkeep, a SIP structure can last as long as a traditional home, if not longer.

Building Back Stronger with SIP Technology

Rebuilding after a natural disaster is an opportunity to turn a new chapter, restore what was lost, and build back stronger and smarter. SIP kits align perfectly with the needs of disaster-stricken communities. They solve the biggest challenges by:

- Going up quickly to reduce agonizing wait times.

- Creating solid, resilient structures that can withstand future storms.

- Delivering cost efficiencies and energy savings when people need them most.

- Empowering communities to take control of the rebuilding process.

Structural Insulated Panel kits are a modern solution to an age-old problem: how to rebuild efficiently and effectively after a disaster. They address the real pain points—providing the strength, speed, and sustainability survivors are looking for.

For anyone facing the daunting task of rebuilding a home and a life after catastrophe, SIP kits offer both practical reliability and peace of mind. It’s a path from devastation to renewal built on confidence and community.

FAQs

SIP kits, or Structural Insulated Panels, are pre-engineered building components that can be assembled quickly and easily. After a natural disaster, when traditional materials and skilled labor are in short supply, they offer a faster, more cost-effective rebuilding option. SIP homes are strong, energy-efficient, and built to withstand harsh weather, making them ideal for areas prone to storms or affected by disasters.

Because SIP panels arrive pre-cut and ready to assemble, construction can often be completed faster. This speed helps families and businesses return to normal life sooner, easing the emotional and financial strain that follows a disaster.

Yes. SIP structures are known for their exceptional strength and rigidity. The panels offer excellent resistance to wind, impact, and shifting forces, often outperforming traditional wood framing. Many SIP homes in hurricane and earthquake zones have remained intact even after severe weather events.

While SIP kits may have a slightly higher upfront cost, they ultimately save money through shorter build times, reduced labor requirements, and lower long-term energy bills. Prefabrication also locks in pricing, helping to avoid the inflated material costs that are common after a disaster.

Yes. SIP systems are highly adaptable and can be engineered to meet regional building codes, climate conditions, and architectural styles. Whether you’re rebuilding a single-family home, a small business, or a community structure, designs can be tailored to achieve strength, efficiency, and a pleasing appearance.